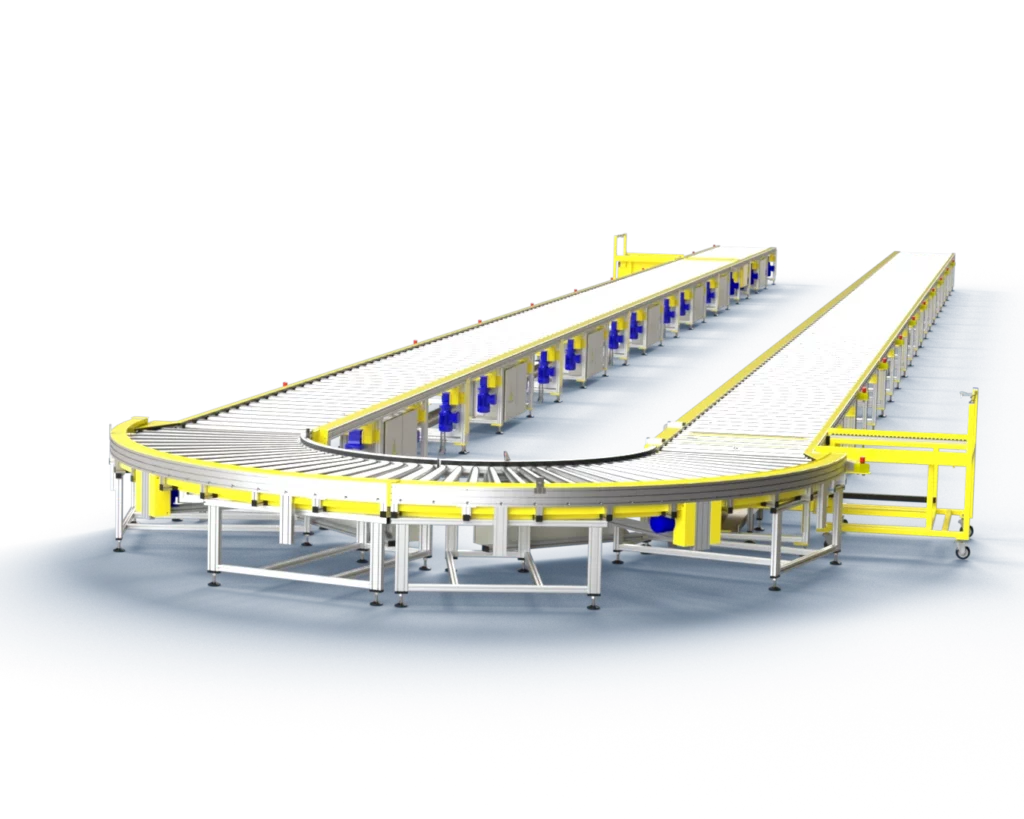

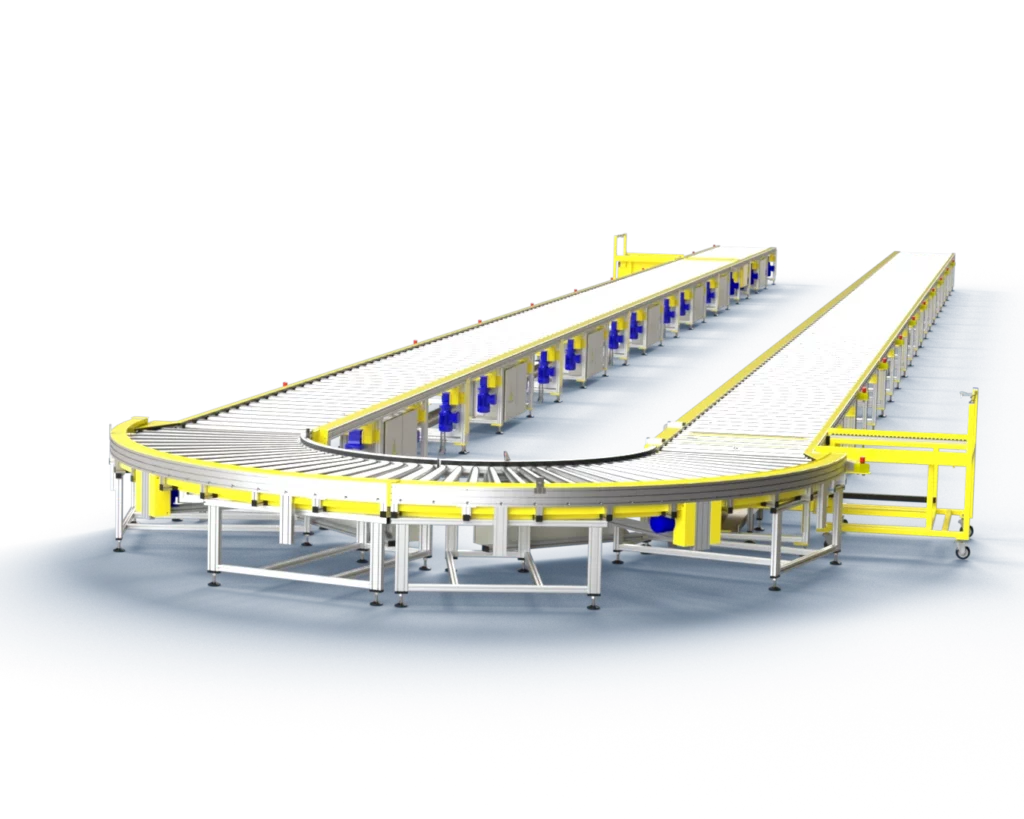

A significant part of JCEE’s production is dedicated to the development and manufacturing of conveyors and logistics systems. These can range from simple roller or belt conveyors to complex logistics applications combining both types, including switches, crossings, or lifts.

But our conveyor offering doesn’t stop there. With our experience in special-purpose machine development, we can equip conveyors with additional production or inspection technologies according to customer requirements. This eliminates the need to coordinate with multiple suppliers and results in a smoother and more efficient project execution.

Need an efficient, reliable custom solution?

Our experts are ready.

We design and supply conveyors, lifts, hoppers, sorting stations, and complete custom lines. We also offer hybrid solutions combining manual handling with automation.

Yes. During system design, we plan integration with your upstream systems. We adapt the solution to your data flows and processes.

Absolutely. Internal logistics is our bread and butter—we’ve handled transport of materials, semi-finished products, packaging, and finished goods in production halls and warehouses.

We adapt flexibly. We schedule installation in phases outside peak hours or on weekends. We can also perform “live” swaps without downtime—but feasibility depends on the site and safety.

Others

Billing Details

JCEE s.r.o.

Dobrovského 602 LANŠKROUN, 563 01 CZECH REPUBLIC

IČ: 46508554

DIČ: CZ46508554

Not sure which solution

is right for you? Contact us and we’ll be happy to help you choose.

+420 734 230 422

© JCEE s.r.o. Všechna práva vyhrazena