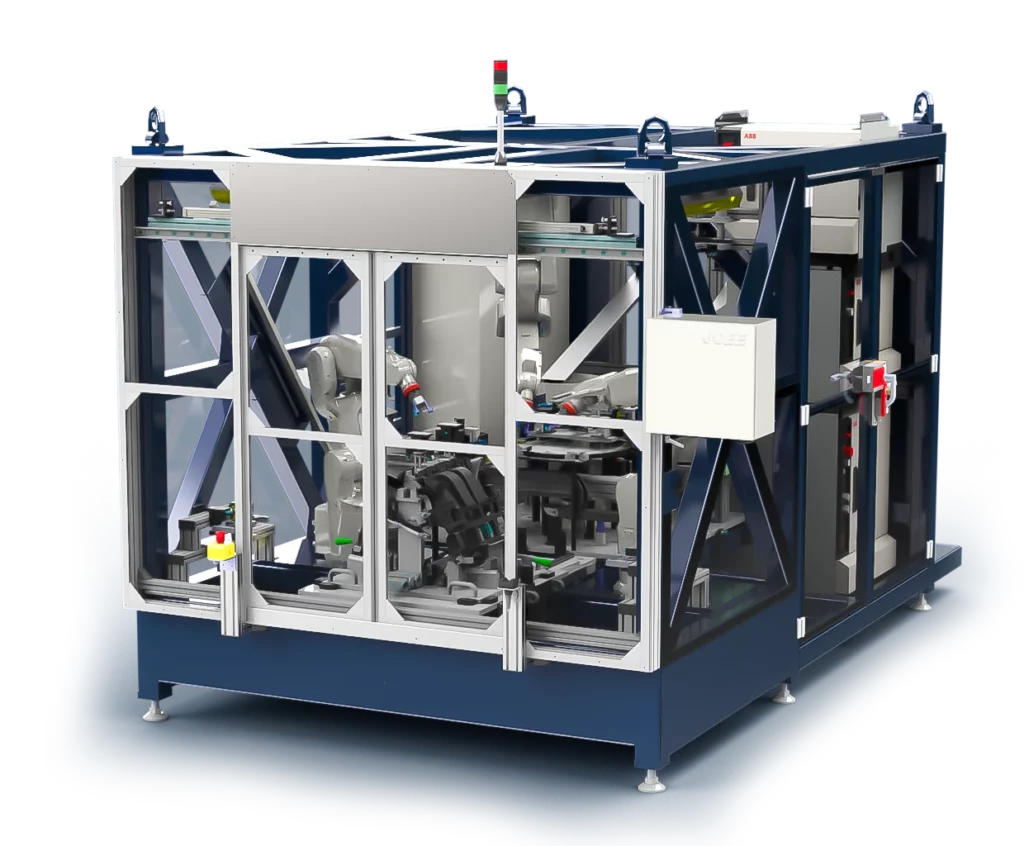

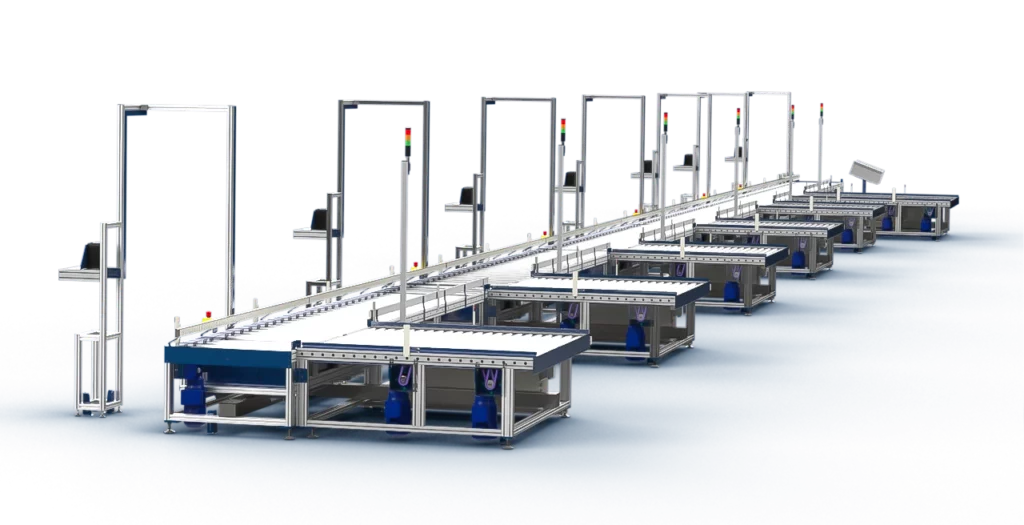

JCEE, s.r.o. specializes in the development and production of automated machines for the automotive and electronics industries. Our goal is to provide comprehensive automation solutions – from initial design to manufacturing, commissioning, and on-site installation at the customer’s facility. We also offer both warranty and post-warranty service to ensure smooth operation and long-term reliability of our equipment.

Need an efficient, reliable custom solution?

Our experts are ready.

We’ll go through your process together, identify suitable areas for automation, and either propose specific solutions or help you prepare tender documentation.

Most tasks—design, engineering, assembly, and programming—are handled in-house by our teams. We outsource only component manufacturing and surface treatment.

It depends on project complexity. Simple systems take about 15 weeks. Complex lines and large systems may take several months, occasionally up to a year.

We don’t limit ourselves to a narrow specialization. With 30 years of experience, we handle a wide range of automated workstations—from inspection to production—in various industries.

Ano. Naše řešení jsou zákaznická a na míru, takže s vámi úzce spolupracujeme od začátku až do konce. Každou klíčovou fázi konstrukce i výroby konzultujeme, a v průběhu vás pravidelně zveme na kontrolní návštěvy. Díky tomu máte celý proces pod dohledem a jistotu, že výsledek bude přesně odpovídat vašim požadavkům.

We respect customer vendor lists. We have experience with many manufacturers of controllers, robots, cameras, and specialized tech and adapt to your preferences.

Yes. We provide warranty and post-warranty service, technical support, and potential modifications according to your production needs.

Others

Billing Details

JCEE s.r.o.

Dobrovského 602 LANŠKROUN, 563 01 CZECH REPUBLIC

IČ: 46508554

DIČ: CZ46508554

Not sure which solution

is right for you? Contact us and we’ll be happy to help you choose.

+420 734 230 422

© JCEE s.r.o. Všechna práva vyhrazena